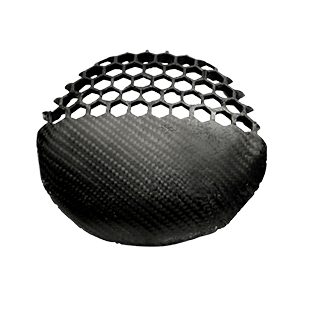

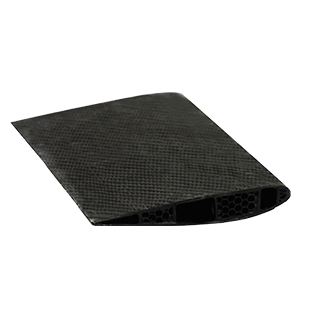

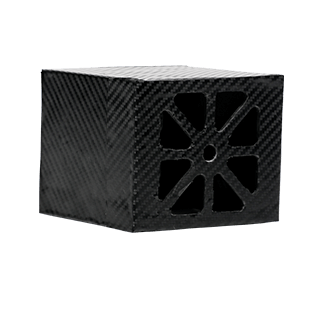

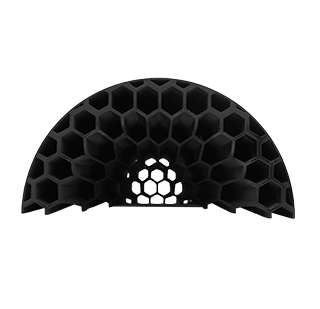

Fabheads offers customized hybrid processes – combining the power, precision and flexibility of Composite 3D printing with the time-tested traditional fabrication processes, we effectively create one overall fabrication process blueprint to make that part perfect – be it in strength, precision and cost effectiveness!

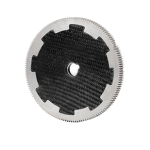

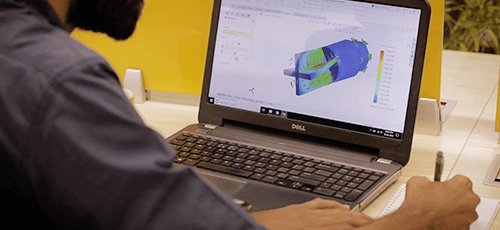

Prototyping

Quick POC or MVP of your product

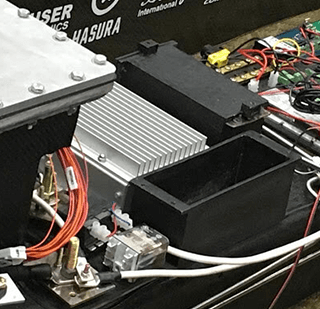

Hybrid Manufacturing

Combine multiple materials for your product

Mass Manufacturing

Take the product to market in large volumes